Winding Insulation Resistance Measurement

I am working in power plant. we have a problem on one of gas generator. the problem is that low winding insulation resistance of generator rotor. it read 800 k ohm where the other generator read greater than 10 M ohm. at full speed, there is no Kv measurement. same time no standing alarm from excitation system. all equipment are indicated okay..

My question is that is the relation between low isolation resistance of generator rotor and Kv measurement?.

Mail from – IB SA Arabia

There is no relation between insulation resistance and any other parameter of you system. Insulation Resistance depends on age, physical damage on windings, humidity, contamination, wear and tear.

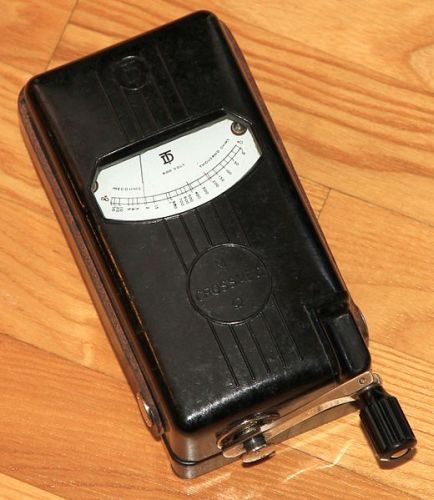

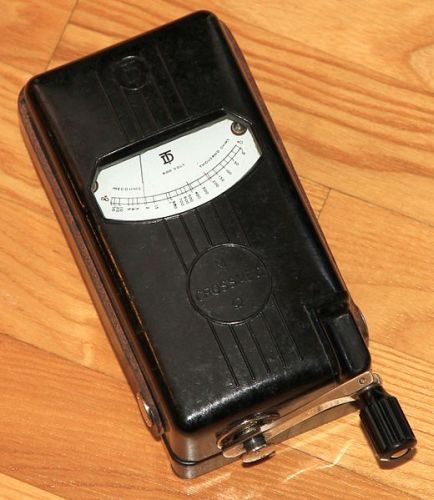

Dana Tekno Crossmeg Insulation Tester

Let me know where you are doing the KV measurement. If you are measuring leakage voltage due to insulation breakdown, you have to fix it. The relationship of parameters does not matter. Small leakages can be tackled with grounding, don’t compromise on safety and quality.

It is possible you may be touching one of the probes when you measure insulation, that may be the 800K, Even if one finger touches the probe, the circuit is closed via earth and a low 1M measurement can be seen.

The rotor the chassis all need to be grounded, and insulation resistance has to be measured after all power connections or electrical connections are removed. The electrical terminations unit should float for proper measurement, especially when you have doubts. Tell me about your progress.

delabs

I did not get a reply later, but i may not have understood the question well. The question also lacks details. In HV breakdown measurements KV is applied, but it has to be done after disconnecting all points. Beyond a limit, HV testing becomes destructive. Leakage Monitoring and Earth Leakage Breakers can be used. Motor/Generator Protection Units too. Even an imbalance in the current or Three phase problems.

It is best to use a Insulation Tester to apply little above Normal Voltage and see leakage, if this is a routine quality check. Better still, have a current sensor on the earth line and use a data logger to keep a tab on the leakage levels, temperature and voltage of all motors and generators. Even sound/vibration sensors will be an advantage. Before these electrical equipment fail many symptoms can be caught by data logging and limit windows. An electronic instrument or Trip Circuit will operate or alert after a fault occurs. Data logging and analysis will warn of a possible Motor or Generator performance degradation. Symptoms Indicate problems, prevention better than cure. Data Recording, Graphs and preemptive measures better than Breakdown Repairs in the Night. Drop in efficiency is an indicator for maintenace, This also prevents mishaps and power wastage.

It is true some insulation faults will show up on vibration and high humidity levels. These have to be simulated. In operation testing has to be done with sensors and recorders for leakage current etc. not insulation resistance.

Learn more about Insulation testing

– delabs