Electronics Product Design

Product Design

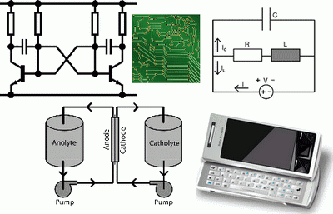

When you wish to Begin to learn Electronics, first a short study of Physics is essential, secondly some Electronics theory. Then build simple and small gadgets to learn Practical Electronics while working with Educational Hobby Circuits. Lastly to make your own product designs, a fundamental knowledge of Analog and Digital Electronics is the foundation for your next steps into Engineering a Design.

Applications and Components

The basic building blocks for most circuits are Chips or ICs. You can acquire considerable knowledge by studying Application notes to start with. When you want to use a Microprocessor or Build Your Own Microcontroller Projects, you can study the IC Datasheets and use an Evaluation Kit with Programmer. The Specifications and Behavior of Passive Components like inductors, capacitors and Resistors; Discrete Semiconductors; Power Devices. and RF Components have to be understood well, in order to design sturdy Industrial Grade Designs

Advanced Engineering

The Technology related to the equipment used for Testing, Troubleshooting and Calibration is called Test & Measurement, Here we use Test Instruments like Oscilloscopes and Digital Multimeters. Medical Electronics and Military Designs require more meticulous, robust and dedicated designs with higher reliability and accuracy. In Medical electronics product safety is vital, Consumer products should be affordable without compromising Human Safety factors. Then you need to look into Usability or Ergonomics, which is a science that helps us develop practical and cost-effective products, which have an optimum Man-Machine Interface. EMI, ESD, RFI are other important aspects that deals with Electromagnetic, Electrostatic and RF; Noise and Interference; in the Stable performance of products in Real World Harsh Environments or the Reliable Transmission of data.

Lastly Computing and Communication makes products more versatile in any application. EDA, Technical Computing and Systems Engineering helps creating products and complete process solutions.

Industrial Automation and Process Control

Automation and Control is the predecessor of Robotics and Mechatronics. A Control system is made of Sensors sending acquired data to a Controller which operates Actuators to manage the process in Real Time. Starting from a Bimetal Thermostat to a SCADA, the controller has grown from mechanical — electrical — analog — digital devices to microcontroller-computer based equipment.

Both in Control Systems and Robotics the Collaboration between Robots or Control Units, leads to the development of wireless network of Interactive, Intelligent and Distributed Self Governing Systems. The outcome is Web Process Automation, Web Applications based Solutions in Monitoring, Analyzing and Configuring these Sophisticated Networked Systems.

delabs design notes – First posted in the frontpage of “delabs circuits” around 2002