CJC or Cold Juction Compensation

About a month agoo I asked a few explanation on blind controller circuit design, up now i did focused on mechanical parts of my rubber press and now these are ready, i turned myself to the controller :

Qestions came up as I tried to duplicate part of your circuit design on a bread board and could not get a significant reading on DMM.

Why value of TH1 is 5 ohm in this circuit …in other circuits you design it is mostly 12 ohm ?

I used document DACT0006.PDF to make TH1 and re-calculate values of resistors involved around OP07 for gain and R26 using formula you gives. R26 : 330K ? to not induce anyone error i won’t replicate here these calcul, but could you confirm me this value ? (sorry for this one I know it is unpleasant : think I’m lost… )

Mail From SY

Another Method using a Copper Resistor

If wires of two dissimilar metals are joined at both the ends and the junction formed at one of the ends, is heated more than the other junction, a current flows in the circuit due to Seebeck thermal emf. This effect is used in thermocouple temperature sensors.

Thermocouple Temperature DPM – DMM

The Peltier effect is the converse of above Seebeck effect, which means that if a current is forced through junctions of dissimilar metals, the junction will generate heat or absorb heat (cooling) depending on direction of the applied emf. This effect is used to make portable and small refrigerators.

delabs

What is the range i should use for DMM for this blind proportional circuit ? what should be the reading ?

Iideal for my purpose will be 1mV per degre Celcius as cheap panel meters range 0- 200mV

One of LM324 operational amplifier output is connected to ground… which is separate from VDD, could you explain me more?

I ‘m making now the box that will contain the circuit and support the press itself. When I get over this stage i will make pictures, is 100Kb suitable size to send you ?

Mail From SY

Yes you can try practically and redesign for any value from 5-12 ohms of copper is fine, the error may be negligible. But when you manufacture in large numbers you should streamline the design. Now just put a 10 ohm and get it started.

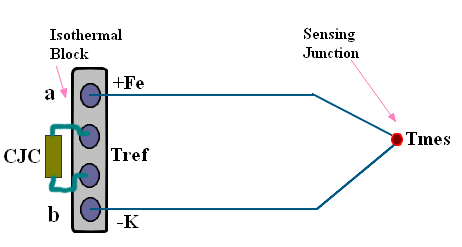

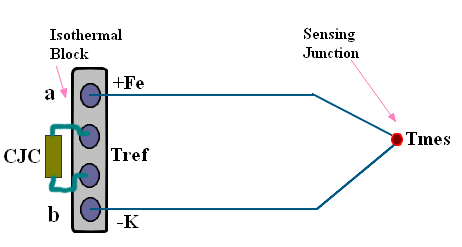

“Maintaining an ice water slurry and actual cold junction is rarely feasible. Typically, the cold junction is omitted, and the potential is measured directly across the two terminal ends of the thermocouple wires at ambient temperature. For historical reasons, we speak of the terminal ends of the thermocouple wires as the cold junction, despite the fact that there is no longer an intentional junction.”

The DMM should be a 10 Megohms input impedance type at 200mV range. The values are quite low for 100 deg we need a10mV from circuit in a 3-1/2 DPM it reads as 100 conts at 200mV range.

In this page Industrial Process Control Circuits

There is a circuit blind proportional temperature controller

This circuit needs a dual supply, like +5 gnd and -5, in order to save cost a 7812 was used with a LM324 creating a virtual GND. The LM324 output is not connected to GND, it is generating the Ground. It is a freak design, bent to adapt to battery opeartion too. You can avoid it by building a descent dual supply with 7805 and 7905, so that it does not complicate your troubleshooting.

A 200mv 3 1/2 dpm is 199.9 mV or 2000 counts to display 250 deg C you need 25mv or 25.0 mV that means 0.1 mV or 100uV per degree, i may be wrong, your question is jogging my old memories. I do not manufacture anymore. But i still design.

Reply from delabs